Empowering Manufacturing Teams to Learn,

Explore & Implement Artificial Intelligence

Read time: 5 mins.

Where & How to Start with

AI in Manufacturing

Since you are reading this I feel that it is safe to assume I do not need to explore reasons WHY for implementing Artificial Intelligence in Manufacturing, so today's newsletter is focused on the where & how to get started.

When building any system or structure, the most important component is a solid foundation, that foundation is your DATA. Not Just ANY DATA… Quality Data

“Quality data is the foundation for AI in manufacturing. Combining actual historical product data and simulated insights expands AI’s field of vision, unlocking new levels of innovation and competitiveness”

Source: Philippe Adam

According to MIT’s Technology Review, “The lack of universal industrial data is a major obstacle to deploying AI among mainstream manufacturers. That’s because manufacturing data is often localized or specific to a particular industry domain or a company’s operations.”

In 2023, the inaugural year of the Rootstock report, the survey found that the top two barriers to digital transformation were a lack of cross-departmental collaboration/coordination (37%) and limited access to data (34%). Source: Survey: 90% of manufacturers are using AI, but many feel they lag behind competitors

Source: Survey: 90% of manufacturers are using AI, but many feel they lag behind competitors

The main take away from the quotes above is that teams need to be intentional about data. Data structure, data collection, and data access. Even if there are a million AI companies out there that are working to solve your specific manufacturing challenges. Your process, your equipment and your data are unique. So, teams need to intentionally build systems infrastructure to not only collect the necessary data, but also be able to centralize and provide access to the data across the organization. Those who do WIN at AI implementation and are innovating much faster than companies that have not even started to be a data driven manufacturing organization.

Which Data:

To make the most out of your limited resources we recommend being intentional about which data you focus on first.

Best Practices to Implement AI in Manufacturing

Identify the Problem: First, break down why you wish to use AI in the first place. Set SMART goals for deploying a chosen solution, which stands for being specific, measurable, achievable, relevant, and time-bound.

Leverage Your Team: Bring together experts within your business, including leaders and those on-the-ground, to evaluate your capabilities and available resources.

Review Data Quality: Check in on your current data sources – is it accessible and sufficient? If not, address this first because all AI is based on the data at hand.

Choose Your Tool: Research and select the type of AI you need. Are you looking to adopt an off-the-shelf solution, hybrid, or customized solution?

Test and Deploy: Get started using your technology by testing it out. Review results, and when everything looks good to go, expand its use cases. Be sure to continuously monitor how your AI in manufacturing is performing. Don’t be afraid to adjust as needed.

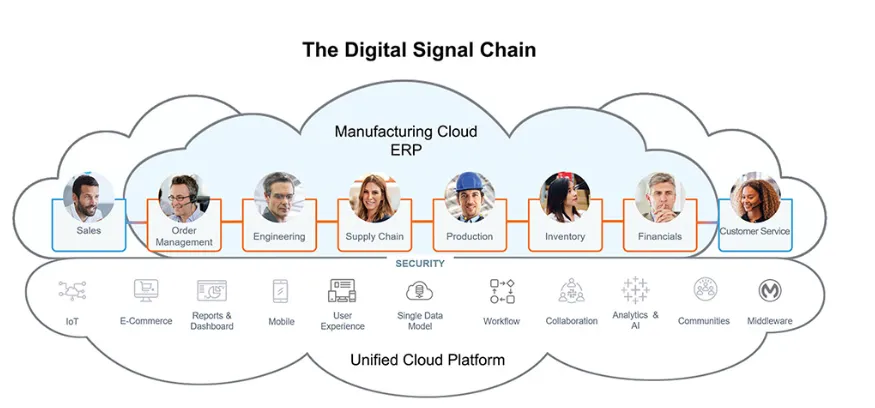

Another important data concept to be aware of when considering your data is Signal Chain: the stream of critical data from across the manufacturing business.

ERP and the Manufacturing Signal Chain

Embracing the Manufacturing Signal Chain

•The Manufacturing Signal Chain is a powerful strategy that has taken root across many manufacturers' operations. This approach helps manufacturers supercharge their digital transformation efforts, while also improving decisioning capabilities.

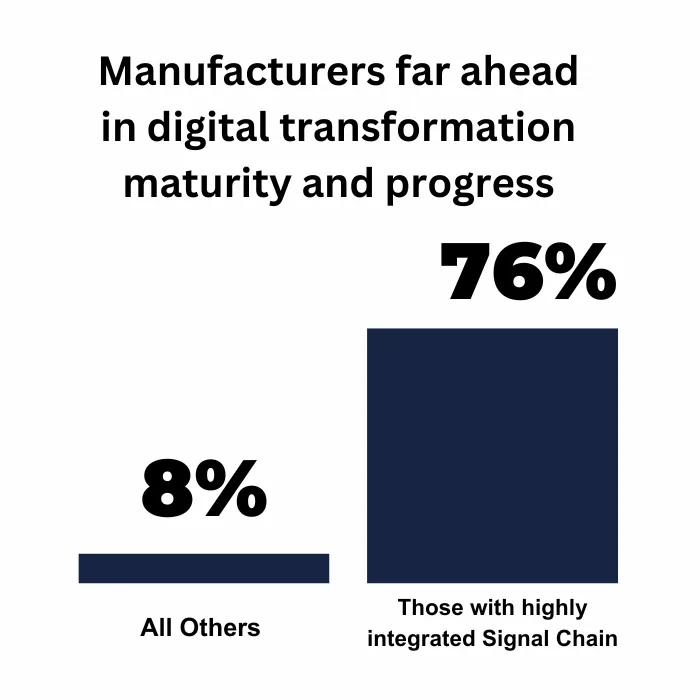

• Our survey results demonstrate this power - among the respondents who are reportedly far ahead of their peers in terms of digital transformation maturity and progress: 76% have been utilizing a Signal Chain strategy; only 8% of those without a Signal Chain strategy have achieved the same progress.

Defining Terms

The Manufacturing Signal Chain utilizes a cloud platform to connect live data streams on customer demand and supply chains, so manufacturers can dynamically balance production capacity.

When augmented with artificial intelligence, the Signal Chain can serve as a Decisioning Platform to help make better, more timely decisions that improve manufacturing operations.

Mapping out your signal chain will help you visualize all of the cross functional and cross departmental data sources that need to be considered as you look to scope your AI in Manufacturing project. A great starting place for this is any existing process maps or Value Steam Maps. Take these existing maps and add data sources that are available or that would need to be available to execute on the project and AI implementation.

The Digital Signal Chain

The adoption of a manufacturing “signal chain” translates to digital transformation success. Manufacturers who have deployed a signal chain strategy are farther ahead in their digital transformation journeys (76%) than those that have not (8%).

Source: Survey: 90% of manufacturers are using AI, but many feel they lag behind competitors

Company Highlights

Snowflake: AI Data Cloud for Manufacturing

Focus: Simple, Secure & Organized Data operations and management

How They Help:

Build a Data foundation to Store, integrate, and govern large volumes of data across IT and OT systems, devices and more. Accessing data in near real time enables data collaboration across partners, suppliers and customers in a secure, scalable way to increase agility and visibility across the entire manufacturing value chain.

Factbird: Manufacturing Intelligence Solutions

Focus: Manufacturing Intelligence solutions

How They Help:

Enhance your manufacturing operations with Factbird's easy-to-setup Manufacturing Intelligence solutions. Collect, manage, and analyze production data from multiple sources to improve your manufacturing operations.

C3AI - Enterprise AI for Manufacturing

Focus: Unified data foundation

How They Help:

Enables global manufacturers to rapidly integrate data from a variety of sources, including internal enterprise applications, sensor networks, operational systems, and exogenous third party data to power AI models. This platform and unified data is the foundation for C3 AI’s SaaS applications to address inventory optimization, predictive maintenance, production schedule optimization, and other high-impact use cases.

Events

LIVE WEBINAR

The trends, headwinds and opportunities for the year ahead

January 28, 2025 | 10:00 AM PT

EVENT

February 12, 2025

Copyright © 2025 AI IN MANUFACTURING, All rights reserved.

Want to change how you receive these emails?

You can unsubscribe from this list.